Lock‑Stitch vs. Saddle‑Stitch: What Every Leather‑Craft Enthusiast Should Know

When you pick up a piece of leather and begin to stitch it together, the type of seam you choose determines not only the look of the finished item but also its durability, flexibility, and how it will age over time. Two of the most common stitching methods in leather-working are the lock‑stitch (often called a chain‑stitch) and the saddle‑stitch. Both have deep roots in traditional craftsmanship, yet they serve very different purposes. In this article we’ll explore the construction, strengths, and ideal applications of each technique, and explain why Huvro relies exclusively on the saddle‑stitch for all of our products.

Anatomy of the Lock‑Stitch

A lock‑stitch is created by looping a single thread around the needle as it passes through the leather. The needle pushes the thread forward, then pulls the loop back through the previous loop, forming a chain‑like series of interlocking knots. This method is sometimes referred to as a “chain‑stitch” because the resulting seam resembles a tiny metal chain.

How It Works

- Thread Placement – A single strand of strong, waxed thread (often polyester or nylon) is loaded onto the needle.

- First Pass – The needle pierces the leather, pulling the thread through and leaving a small loop on the exit side.

- Loop Capture – On the return stroke, the needle catches the loop and pulls it through, locking the new loop around the previous one.

- Repeat – Each subsequent pass repeats the capture process, creating a continuous chain of interlocked loops.

Advantages

- Speed – Because only one thread is used, the lock‑stitch can be executed quickly, especially with a sewing machine equipped for leather.

- Flexibility – The chain‑like structure allows the seam to flex more readily, making it suitable for items that need to bend repeatedly, such as belts or straps.

- Aesthetic Appeal – The visible chain pattern can be decorative, adding a subtle visual texture to the seam.

Limitations

- Strength Dependency – The overall strength of a lock‑stitch hinges on the integrity of a single thread. If that thread frays or breaks, the entire seam can fail.

- Limited Load‑Bearing – For heavy‑duty applications—think backpacks, saddles, or large wallets—the lock‑stitch may not provide sufficient tensile strength.

- Potential for Slippage – Under extreme tension, the interlocking loops can slip, especially if the thread is not properly waxed or if the leather is overly stiff.

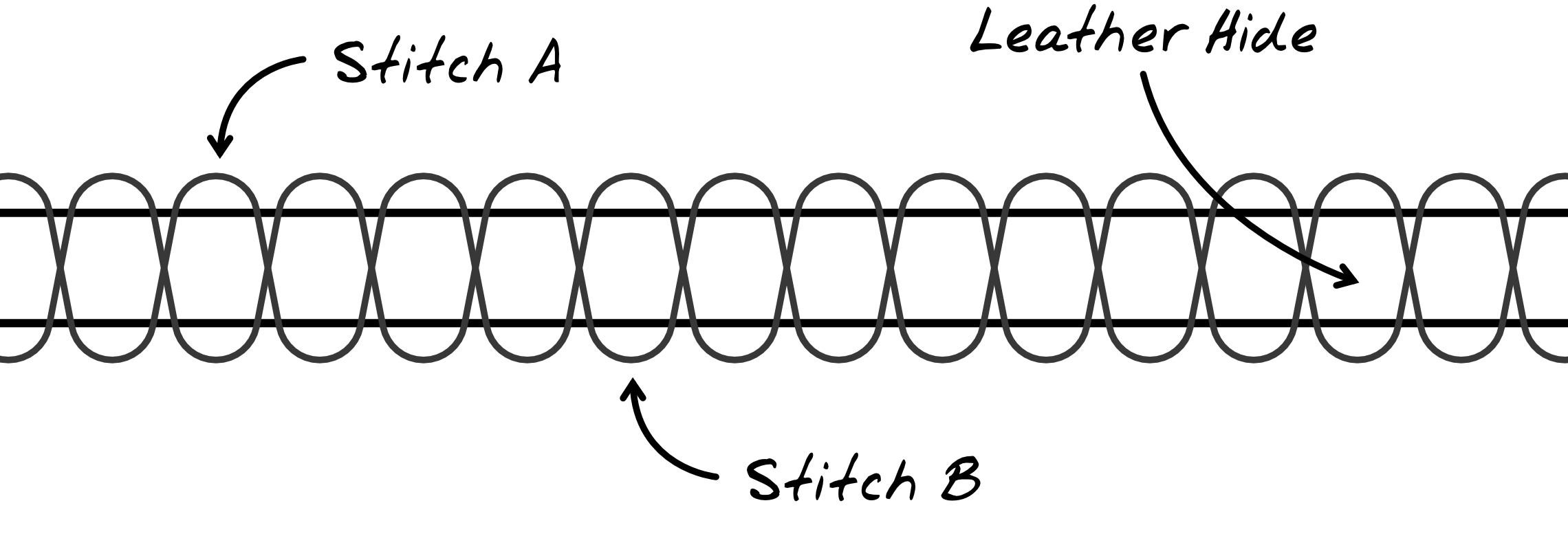

Anatomy of the Saddle‑Stitch

The saddle‑stitch, also known as a “double‑needle” or “hand‑stitched” seam, employs two needles and two threads that run in opposite directions. Each needle pierces the leather independently, and the threads are tied together at the end of the seam. The result is a pair of parallel stitches that mirror each other, creating a symmetrical, highly robust seam.

How It Works

How It Works

- Dual Needles – Two needles, each threaded with its own strand of waxed thread (commonly polyester, nylon, or linen), are positioned side‑by‑side.

- Simultaneous Piercing – Both needles enter the leather at the same point, emerging a short distance apart on the other side.

- Parallel Stitch Formation – As the needles are withdrawn, each thread forms its own line of stitching. Because the needles travel together, the two lines stay perfectly aligned.

- Knotting – Once the seam reaches its endpoint, the two threads are tied together with a secure knot (often a surgeon’s knot or a double‑overhand).

Advantages

- Exceptional Strength – With two independent threads sharing the load, a saddle‑stitch can withstand far greater tension than a single‑thread lock‑stitch. Even if one thread begins to fray, the second thread continues to hold the seam.

- Redundancy – The dual‑thread design provides built‑in redundancy, a crucial safety factor for gear that carries weight or experiences stress.

- Clean Aesthetic – The parallel lines produce a crisp, professional appearance that many leather artisans consider the hallmark of quality workmanship.

- Longevity – Because the threads are typically waxed and the stitching is hand‑driven, the seam resists abrasion and environmental degradation better than many machine‑stitched alternatives.

Limitations

- Time‑Intensive – Hand‑stitching a saddle‑stitch takes longer than a lock‑stitch, especially on larger pieces.

- Skill Requirement – Achieving evenly spaced, consistent stitches demands practice and a steady hand.

- Equipment – While a basic stitching chisel and needles suffice, many artisans invest in specialized saddle‑stitch awls or stitching frames to maintain uniformity.

When to Choose One Over the Other

| Application | Recommended Stitch | Why |

|---|---|---|

| Light‑weight belts, decorative straps | Lock‑stitch | Faster, flexible, visually appealing |

| Heavy‑duty backpacks, satchels, tool holsters | Saddle‑stitch | Superior load‑bearing capacity, redundancy |

| Premium leather goods (wallets, briefcases, luxury bags) | Saddle‑stitch | Professional finish, long‑term durability |

| Items requiring frequent bending (e.g., watch straps) | Lock‑stitch (if flexibility outweighs load) | Allows greater movement without stressing a single thread |

| Production runs where speed is critical and load is modest | Lock‑stitch (machine) | Efficient for volume while maintaining acceptable strength |

In practice, many leather workshops employ both techniques, selecting the seam based on the specific functional demands of each component.

Why Huvro Uses Saddle‑Stitch Exclusively

At Huvro, we have made a deliberate decision to adopt the saddle‑stitch as the sole stitching method across our entire product line. This choice reflects our commitment to three core principles: strength, reliability, and craftsmanship.

- Uncompromising Strength – Our customers rely on Huvro accessories—whether it’s a rugged journal cover, a daily‑use wallet, or a custom‑crafted strap—to endure demanding environments. By employing a double‑thread saddle‑stitch, each seam bears twice the load of a comparable lock‑stitch, providing peace of mind that the product will hold up under heavy use.

- Built‑In Redundancy – Accidental snags, abrasions, or exposure to harsh weather can weaken a single thread. With two independent threads running side‑by‑side, a compromised strand does not jeopardize the entire seam. This redundancy aligns with our philosophy of designing products that last a lifetime, not just a season.

- Artisanal Aesthetic – The clean, parallel lines of a saddle‑stitch convey a sense of intentional, hand‑crafted quality. Our brand identity revolves around meticulous attention to detail, and the visible stitching is a signature that signals to our community that a piece was assembled with care, not rushed by machines.

- Consistency Across Materials – Huvro works with a variety of leathers—from supple vegetable‑tanned calfskin to thick, oil‑finished cowhide. The saddle‑stitch performs reliably across this spectrum, whereas a lock‑stitch can behave unpredictably on very thick or very soft hides.

By standardizing on saddle‑stitch, we also streamline our production workflow. Our artisans become masters of a single, highly refined technique, reducing variability and ensuring that every Huvro item meets the same exacting standards.

Practical Tips for Mastering the Saddle‑Stitch

Even though the saddle‑stitch is straightforward in concept, achieving flawless execution requires a few best practices:

- Choose the Right Thread – Waxed polyester or nylon offers excellent tensile strength and resistance to moisture. For a classic look, linen thread can be used, but it should still be waxed for durability.

- Maintain Consistent Stitch Spacing – Use a stitching chisel or a marking gauge to pre‑punch holes at equal intervals (typically 3–4 mm apart). Uniform spacing prevents uneven tension and keeps the seam straight.

- Keep Tension Balanced – Pull each thread gently as you work; over-tightening can cause the leather to pucker, while too loose a tension leads to sloppy seams.

- Finish with a Secure Knot – After completing the seam, tie a surgeon’s knot followed by a few half‑hitches. Trim excess thread close to the knot to avoid snagging.

- Test Before Final Assembly – Run a quick pull test on a scrap piece of the same leather to confirm that the stitch holds the expected load.

Conclusion

Understanding the mechanical and aesthetic differences between lock‑stitch and saddle‑stitch empowers you to select the right seam for any leather project. While the lock‑stitch offers speed and flexibility, its single‑thread nature limits its load‑bearing capacity. The saddle‑stitch, with its dual‑thread redundancy and clean appearance, stands out as the premier choice for durable, high‑quality leather goods.

At Huvro, we have embraced the saddle‑stitch as the backbone of our manufacturing process because it embodies the durability, reliability, and artisanal excellence that our brand promises. Whether you’re a seasoned leather-worker or a newcomer eager to craft a lasting piece, mastering the saddle‑stitch will elevate the strength and professionalism of your creations.

Happy stitching, and may your seams be as steadfast as the leather they bind!

Leave a Reply

You must be logged in to post a comment.